-

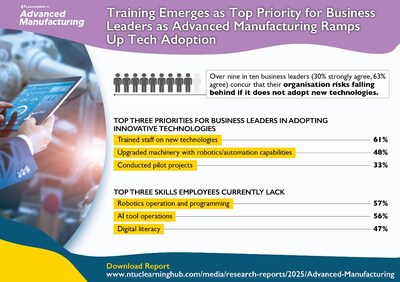

Over nine in ten business leaders (30% strongly agree, 63% agree) concur that their organisation risks falling behind if it does not adopt new technologies.

-

In adopting innovative technologies in advanced manufacturing, employee training is the top priority (61%) for business leaders, alongside upgrading machinery with robotics/automation capabilities (48%) and conducting pilot projects (33%).

-

Nearly three in four (71%) leaders say their workforce is well-prepared for the shift towards technology-enabled manufacturing, but most still lack in-demand skills like robotics operation and programming (57%), artificial intelligence (AI) tool operation (56%) and digital literacy (47%).

SINGAPORE, Nov. 7, 2025 /PRNewswire/ — As Singapore’s manufacturing sector accelerates towards advanced, technology-enabled production, over nine in ten business leaders (30% strongly agree, 63% agree) concur that their organisation risks falling behind if it fails to adopt new technologies.

To stay ahead, companies are investing in both people and technology. Employee training on new technologies (61%) ranks as the top priority taken by business leaders to advance technology adoption, followed by upgrading machinery with robotics/automation capabilities (48%) and conducting pilot projects (33%).

These are some of the key findings from NTUC LearningHub’s Industry Insights Report on Advanced Manufacturing, which surveyed 250 business leaders to explore the current landscape of the advanced manufacturing sector in Singapore, focusing on how advancements in technology, in particular AI solutions, robotics and automation, the Internet of Things (IoT) and process improvement and automation, are reshaping the sector. In addition, the report examines the implications of these trends on the workforce, including training needs, in-demand skills, and job opportunities.

According to the report, nearly three in four business leaders (71%) believe their workforce is well-prepared for the shift towards technology-enabled manufacturing but most still lack in-demand skills like robotics operation and programming (57%), artificial intelligence (AI) tool operation (56%) and digital literacy (47%).

To build these capabilities, manufacturers are expanding their hiring pipelines. Business leaders are most inclined to hire systems integration engineers (36%), robotics operators/technicians (35%), AI/data analysts (31%), followed by digital transformation managers (31%) and automation specialists (30%).

Additionally, about nine in ten business leaders (24% strongly agree, 67% agree) believe that the rise of innovative technologies in advanced manufacturing will lead to the creation of new job opportunities. Business leaders identify robotics programming and maintenance (38%), human–robot collaboration coordination (35%) and process optimisation consulting (28%) as the top areas where new job functions will emerge.