Lafayette, of all places, could become a major player in the drone industry.

Earlier this month, global drone manufacturer DMR Technologies announced it will house its manufacturing base in Lafayette, where it will employ more than 500 people and build its Field Ranger X50. The 10-foot by 10-foot device can weigh 220 pounds when its 13-gallon tank is full and fly for nine minutes on a fully charged battery.

The announcement was the latest of several by drone companies that are setting up shop in the Acadiana area, spawning a new industry sector in the process. Others include logistics company Blueflite and services company FlyGuys.

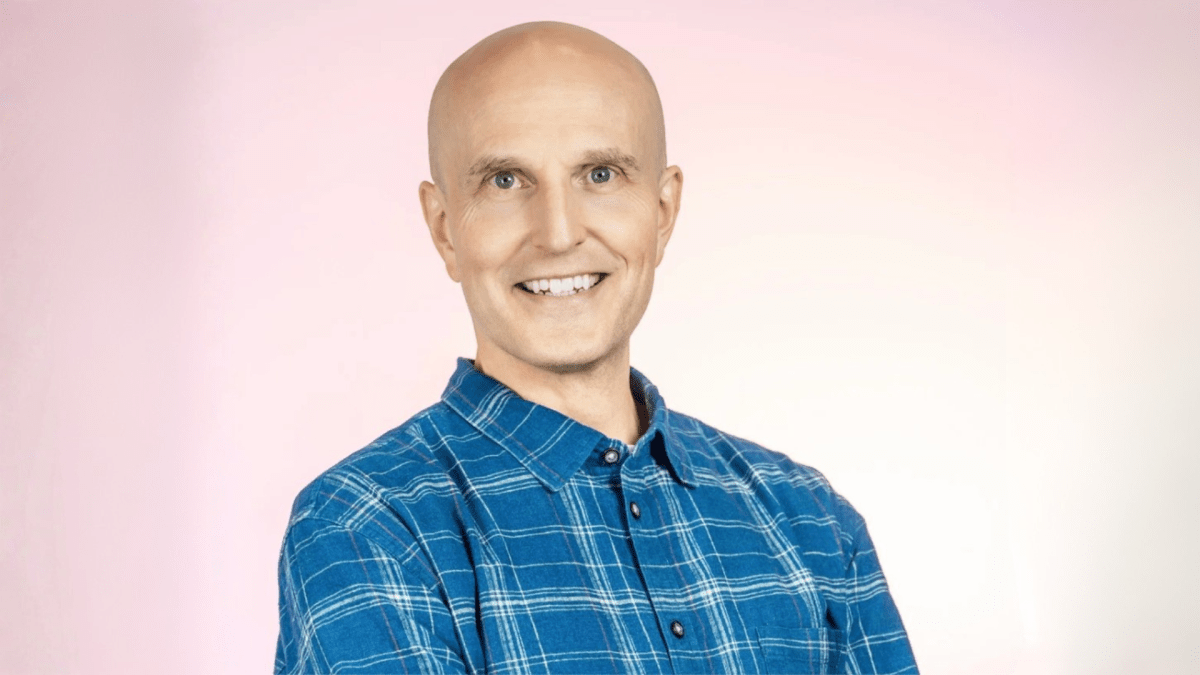

Bruce Bosworth is among the local players in this emerging field, which has the potential to alter the way many businesses in operate in the decades to come. He spent 22 years in the U.S. Navy before founding SoLa Drones, based in Scott, in 2023 with his son Jack.

SoLA Drones is now partnering with DMR on its Louisiana venture. In this week’s Talking Business, the Bosworths discuss their relationship with DMR, why the drone industry can do well in Lafayette and the company’s plans for the old Reptile Tannery of Louisiana building.

This interview has been edited for clarity.

Tell me about the X50 and how it can be used. What makes this model unique?

Bruce: It’s designed for a number of things but primarily herbicides or pesticides for agricultural purposes. So if you have rice, sugar cane, soybeans — all those crops we have in Louisiana — it does a great job. We’ve got a couple of these right now that are being used for sugar cane. The first results are coming back from the sugar mills right now, and they’re very positive, well above the mill average.

And this replaces the traditional human pilot spraying acres of crops from the air?

Bruce: Obviously it doesn’t have the capacity of an airplane. However, for safety purposes, there’s no risk. It’s well-defined within a small area. It doesn’t make any loud noise. It’s not flying over tree lines or near power lines. If we do get close, it’s got an obstacle avoidance radar so you can very safely navigate lines and power lines and get much, much closer than you can with an airplane. You can cover much more of that field precisely.

DMR has a global footprint but is expanding into the U.S. market. You all are a young company. How did the two of you get connected?

Jack: They originally reached out to us as they were entering the U.S. market. We came aboard originally as dealers and distributors for them, but as the market changed and drones — (global drone leader) DJI specifically — became more difficult to get, we explored different opportunities to partner with them. We realized with onshoring, distribution, manufacturing and assembly, there was a huge potential there. We worked with some partners to kind of put that together here.

What role is Lafayette going to play in the production? And why is this area key to its future?

Bruce: Lafayette is going to be their flagship facility for assembly and manufacturing, and the other locations — Kentucky, Alabama, Michigan — are going to remain as distribution and sale partners. Manufacturing will be here. It’s just Louisiana and the pro-business climate that we have. And the Gulf South region and the climate year-round (works) for the ag spraying. We’re the nation’s leader in sugar cane and No. 2 in rice. It just made sense that it start somewhere that’s got a great city, great infrastructure and close proximity to agriculture.

You were in the Navy for 22 years. How did you transition into this industry and find a niche so quickly?

Bruce: I grew up in Fort Worth, did a full career and retired from the military and moved back to Lafayette. I always wanted to have my own business, and we were interested in drones. With the proximity to agriculture and what was going on, we recognized that spray drones were coming on board. So we taught ourselves how to do that and fly it. That led to Jack joining me, and he was like, let’s figure out where we can take this. This represents a neat opportunity for us to grow as a business and a partnership with a more established and larger group.

What’s next in this process? When will the first X50 roll out of the Lafayette facility?

Bruce: We’ll get the first dozen or two dozen key hires to help with the assembly and manufacturing piece, starting with the X50. Then we’ll add in more fabrication and manufacturing capability. By the end of 2027, we should be fully up and running on some of those different product lines. But the next three months, we’re really focused on establishing and renovating this facility. The first quarter next year is when we’ll start pushing products out the door. Hopefully as early as January.